Factory and Warehouse Cooling

Most warehouses need to maintain a particular ambient temperature, either for the health and well-being of the on-site workers or to protect the stock and machinery.

We provide commercial clients across the UK with tailored cooling solutions for their factories and warehouses. Designed by experienced engineers and using the latest in evaporative cooling technology, we can ensure a reliable temperature for any large building. Contact OKEL today to discuss the best cooling solution for your factory or warehouse or to arrange a free consultation with one of our experts.

Why Choose OKEL?

Accredited Engineers

Tailored System Designs

Energy Efficient Systems

20+ Years Industry Experience

Green Funding Payment Options

Quality and Safe Installations

We understand the importance of a safe environment. When the health of vulnerable and elderly residents is at risk, you know you can count on OKEL. No care home resident should have to deal with heating outages and hot water is a necessity. We know you’ll want total confidence in our heating engineers, that’s why our team is fully trained and qualified for the job and have years of experience installing heating solutions in the care home sector.

By assigning your project to our team you’ll be assured that all our lead commercial heating engineers are fully registered with GasSafe and bring a minimum of 25 years’ experience to every job.

In addition, our engineers have a wealth of experience in heating care homes and will carefully plan the installation to ensure any loss of heat or hot water is minimal, carried out during agreed times to ensure no impact on planned activities.

Energy-Efficient Cooling Systems for Industrial Units

Every factory and warehouse has its own unique heating, cooling, and hot water requirements, which is why we offer a design and installation solution carefully tailored to meet those needs.

Our process begins with an on-site consultation to discuss what you need regarding temperature control. We’ll perform a survey of the site to ensure that your equipment and staff’s needs are taken into consideration. From there, we’re able to design the ideal low-energy solution to provide optimal comfort levels in a cost-efficient manner.

We know how challenging and expensive cooling can be, and with the rising cost of energy, it’s essential to consider running costs in our overall designs. We create cost-effective designs that include the highest efficiency equipment from leading manufacturers. Not to mention, all of our systems are Hydrogen Ready. Meaning they’re designed and capable of blending up to 20% Hydrogen with natural gas for when this greener hybrid fuel type becomes readily available throughout the UK’s gas distribution networks.

We treat each cooling system installation as a brand-new project. Most warehouses have their unique layout, which means a one-size-fits-all approach is unlikely to be effective.

We visit your site in person to conduct a full survey and assess your cooling needs. Our experienced engineers will then use that information to design and install a system that meets each of those requirements.

You’ll be assigned your project manager, whose job is to liaise between you and our team. This ensures you have a single point of contact should you have any concerns or queries and that you will deal with someone who knows the project and its current status.

Customer Testimonials

What are the Benefits to OKEL Solutions?

- Bespoke Heating & Cooling

- Energy Efficient Designs

- Cost-effective Systems

- Modern Low-Carbon Technology

- Fully Modulated Technology

- Annual Maintenance Support Packages

- Comprehensive Manufacturers Warranties

- National Support

Our Process

1

Initial Consultation

2

Pre-Installation Planning

3

Installation

4

Handover and Aftercare

Large Scale Financial and Energy Savings

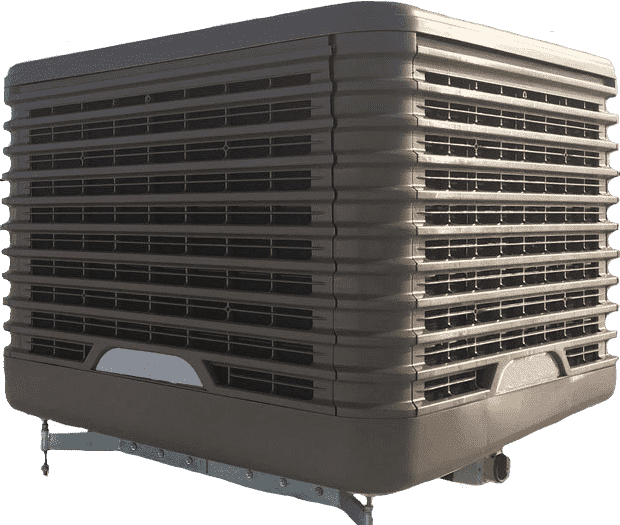

All our systems are designed to be energy efficient, even for warehouses with large floor space. Whether we’re fitting evaporative coolers, air conditioning units, or a mechanical ventilation system, we consider all possibilities to provide you with a cost-effective alternative. From the smallest trade units to large buildings with hundreds of staff, we never back down from a challenge. We know how to design high-performance systems that offer optimal efficiency no matter how big or small the property is.

Our Net Zero Commitment

With challenging targets being set by the government to steer the UK to net zero by 2050, it’s essential that as businesses we all do our part to achieve the stringent targets set out.

When planning our bespoke designs, we always have “Energy Saving” at the front of our mind which reassures you that your system is of the highest efficiency. This can play a key role in helping you showcase the steps you’re taking as a business to successfully achieve green accreditations and targets.

Read Our Factory and Warehouse Cooling Case Studies

Evaporative Cooling System for 360 Vision Technology

Dates: August 2021

FAQs

The capital costs required to install an air-cooling system for your factory or warehouse depend on several factors, including the size of the site, how much equipment is needed for the system to work, and how long the installation is likely to take.

We pride ourselves on delivering value for money to all our commercial clients, offering affordable cooling solutions throughout the UK that provide a great return on investment. During the planning phase, our engineers will give you free and fully costed estimates of your cooling costs, along with a formal quotation.

It is not recommended that you choose to install your own evaporative cooling system since effective cool air systems are about more than technology.

We don’t just install your equipment for you, we design and plan the perfect environmentally friendly solution that maintains the ideal temperature during hot days and cool days alike. Without our decades of experience in the industry, you can’t expect the devices you buy to effectively cool your facility in the same way.

Given the simplicity of the design, an evaporative cooling system is far less expensive to run than more traditional air conditioning systems, as it uses much less energy and has the added advantage of free cooling.

Installation times, much like the costs, depend on the size and complexity of the project. They can also be affected by how much access we have to your warehouse. Our engineers will try their best to work within your schedule so as not to disrupt your workers.

During the planning phase, they will work with you to put together an installation timetable that is well-suited to your facility and allows your team to get on with their jobs with minimal interruption.

Most warehouses and factories require a cooling system for one of two reasons. The first is for the comfort and safety of their workers, as excessive heat often leads to an unsafe working environment. The second relates to the stock or plant in the building. Whether machinery needs to be kept from overheating or products need to be chilled during storage, an appropriate cooling system is essential.

There are several reasons why your factory or warehouse gets too hot. These are just some of the most common ones:

- Machinery. Most mechanical devices give energy in the form of heat, simply as an operational by-product. Moving parts generate friction, which warms up the components and, in turn, heats the air around them. Put enough machines in a confined space and you can expect the air temperature to rise accordingly.

- People. It’s not just machines that generate heat during a normal working day. Your workers also contribute to the temperatures in the factory or warehouse. If they’re working hard, all that energy and exertion can soon cause things to heat up.

- Lack of Ventilation. Between machinery and workers, it’s not surprising that warehouses and factories experience raised temperatures. With no ventilation providing a decent airflow, all that heat has nowhere to go but circulate around the building.