Trust Factory Heating Solution Experts

- Successfully designed and installed large-scale factory heating systems across the UK.

- Solutions bespoke to your requirements with comfort and energy efficiency at the heart of all designs.

- Excellent relationships with industry-leading manufacturers and access to their most advanced, energy-efficient heating systems and controls.

- Gas Safe and NICEIC electrical engineers can deliver a one-stop shop for your gas-fired or electric heating designs and installations.

- Experience with challenging poorly insulated buildings, new builds, and open-plan areas of over 100,000 sq ft.

Get in touch to arrange a FREE factory heating consultation with one of our experts.

Why choose a High-Efficiency Heating System for my Factory?

Reduced energy costs

With the ever-increasing price of fuel and soaring energy tariffs, now more than ever businesses must ensure that their existing heating systems are fit for purpose and of the highest efficiencies to prevent wasted energy and rising energy costs.

Efficient temperature control

Many manufacturing industries, such as steel, moulding, and food manufacturing, are reliant on precise and consistent temperature control. Control is achieved through heating specific areas and expensive plant machinery to ensure product quality and process efficiency.

Fully compliant with temperature regulations

Temperatures in the indoor workplace are covered by the Workplace (Health, Safety and Welfare) Regulations 1992, which places a legal obligation on employers to provide a ‘reasonable’ temperature in the workplace.

The Approved Code of Practice suggests the minimum temperature in a workplace should be at least 16 degrees Celsius. Unless the work involves rigorous physical effort, then it is 13 degrees Celsius. These temperatures are not absolute legal requirements; the employer must determine what reasonable comfort will be in the individual circumstance.

The Approved Code of Practice suggests the minimum temperature in a workplace should normally be at least 16 degrees Celsius, if however, the work involves rigorous physical effort, the temperature should be at least 13 degrees Celsius. These temperatures are not absolute legal requirements; the employer has a duty to determine what reasonable comfort will be in the individual circumstance.

Find the Perfect Factory Heating Solution

Contact our team to discuss your project requirements

Why Choose OKEL for your Factory Heating?

With energy tariffs continuing to soar, heating your factory can be amongst the biggest expenses you have and it’s essential that you have confidence in the company that you entrust to deliver your heating project so not to get it wrong. We have great experience in successfully designing and installing large scale factory heating systems across the UK, including challenging poorly insulated buildings, new builds, and open plan areas in excess of 100,000 sq ft.

Tailored designs for cost effective solutions

Our designs are tailored to your individual requirements and with comfort and energy efficiency at the heart of all our designs to ensure a cost-effective solution and running costs kept to a minimum.

We are able to support you with estimated running costs of your new system so you can factor in ongoing operational costs and decision-making if deciding between 2 different fuel types.

Skilled and experienced factory heating engineers

With commercial installation teams consisting of both Gas Safe and NICEIC electrical engineers, we can deliver a one stop shop for either gas fired or electric heating designs and installations so whatever your fuel preference we have a solution for you.

Proven success with clients

We can showcase our previous works by arranging visits to existing OKEL customer sites to see heating systems in operation that have been designed and installed by our team.

Relationships with quality manufacturers

Excellent relationships with industry leading heating manufacturers and with access to their most advanced, energy efficient heating systems and controls.

Quality care after installation

Continued support after the installation and offer annual maintenance checks to ensure your new heating system operates as effectively as when it was first installed and is maintained in accordance with the manufacturer’s warranty terms and Gas Safety regulations.

How to Heat a Factory?

Delivering an efficient and effective heating solution for large factory premises can present several challenges for our design team. Great care and attention must be taken from the start to ensure we fully understand and deliver against your project brief.

To help heat your factory efficiently, there are several factors that our team must consider:

- Age of the building and levels of insulation.

- Dimensions and maximum height to the apex.

- The ideal temperature for the customer to achieve quality manufacturing.

- Health and Safety guidance for working temperatures.

- Manufacturing processes and onsite machinery and whether these generate heat.

- Layout of the area; mezzanine floors, plant machinery and office space.

- Extraction systems.

- Fuel types on-site, including spare capacity on metres.

- Hours of operation.

- Future operational running costs.

OKEL’s chosen design maximises efficiency by ensuring all the areas highlighted above are factored into the initial planning and design stages and that the equipment chosen for each customer project is of the highest efficiency and supported by intelligent self-optimising controls to achieve optimum performance throughout the year.

No matter what type of industry you’re working in there are two main heating concepts to consider: warm air and radiant heating.

Benefits of Heating Your Factory with Warm Air Heating

The most modern and effective approach to heating large open-plan spaces. OKEL specialises in the bespoke design and installation of warm air heating systems. These machines work by warming the air and use the integrated fans to move the warm air around, providing an even distribution of heat throughout the whole area. Here are just some of the benefits of OKEL’s warm air heating designs:

Multiple fuel options are available such as Natural Gas, LPG, and Electric.

ERP Compliant following the latest Eco Design Directive.

Hydrogen Blend Ready – with natural gas fired models being ready to blend natural gas with up to 30% hydrogen.

Fully modulating heaters that minimise energy usage by using only the necessary kW of heat to maintain a steady and desired temperature throughout the factory.

Wall- or ceiling-mount designs that will ensure the heaters are out of harm’s way whilst creating factory floor space.

Range of sizes to suit various spaces.

Horizontal and vertical air distribution to blow warm air in any direction.

Excellent airflow by minimising hot and cold spots.

Models have a summer ventilation mode to deliver continuous air circulation throughout the premises in the warmer months.

Ability to connect to a Building Management System.

Intelligent user-friendly controls to deliver optimum performance.

Systems individually designed with combined destratification to maximise efficiency by delivering an even distribution of warm air and preventing heat loss from above.

We also offer Comprehensive manufacturer warranties to give continued peace of mind. Overall, you can see energy savings of up to 30% with OKEL’s carefully thought-out warm air designs. View our SIG Trading Case Study to see how we reduced their energy consumption and cut back on energy costs

An expertly designed warm air and destratification system can reduce energy consumption by up to

Benefits of Heating Your Factory with Radiant Heating

Perfect for spot heating, particularly in poorly insulated open-plan areas, Radiant heating provides an efficient, cost-saving solution by heating only the people or objects that it meets. The effect of radiant heat is felt almost immediately and it ensures a long period of retained heat so that the tubes can be switched off well before the end of the working day, making it an efficient and cost-effective solution. Here are just some benefits of using radiant heating:

- No air movement, which is perfect for dusty environments.

- Rapid heat-up time and long periods of retained heat.

- Provides spot localised heating or complete coverage.

- Minimises heat losses in poorly insulated buildings.

- Does not directly heat the air, heating only people or objects that it encounters.

- Multiple fuel options are available such as Natural Gas, Electric and LPG fuel types.

- Low noise level.

- Low energy consumption.

Our Process

1

Initial Consultation

2

Pre-Installation Planning

3

Installation

4

Handover and Aftercare

OKEL’s Most Popular Factory Heaters Include:

Factory Heating Testimonials

“We enjoyed great service from OKEL throughout the process. From the initial survey, a professional proposal, help with landlord & regulatory approvals, great planning and an efficient install that worked around our business needs, we were delighted. We would recommend them without reservation.”

“From initial contact to the commissioning team OKEL performed at every level to ensure the designed heating and destratification system was seamlessly installed throughout our factory. Working in partnership with both their heating and electrical engineers we incurred minimal disruptions to operations and with the majority of works conducted 15 metres above the whole factory. It was a pleasure to work with a knowledgeable and professional business and would highly recommend them.”

Phillip Ward – Operations Director – Strongdor

“Mark and his team were First Class. The heating system OKEL installed is extremely neat and works well and I would not hesitate to recommend them to other companies for industrial heating.”

Anthony Jewell – Managing Director – Anilox Laser Technology

“After the initial installation we had some questions around the heater controls, OKEL were quick to provide support, and it was reassuring to know that the personalised customer service continued after the sale”

Steve Connolly – Operations Director – Downland Bedding

“Phil and Isaac were very pleasant to have on site, I wish everyone we dealt with worked as effectively and considerately as they did”

Adrian McGreevy – Managing Director – 2020 Fluid Power Products

Factory Heating Case Studies

Sig Trading LTD

Downland Bedding

Fortress Technology Europe

Garrandale LTD

Manchester Precision Engineering

Thomas the Baker

Medstrom LTD

Frequently Asked Questions

Your new installation will be in safe hands with our teams of highly skilled Gas Safe & NICEIC registered commercial engineers. We provide rigorous attention to detail and a flexible approach to your installation to ensure minimal disturbance to the day-to-day running of your business.

Our lead engineers each have over 25 years of experience in their trade and our investment in experienced engineers ensures that your heating project will be completed to the highest quality standards, delivered on time, and within the rigorous health and safety protocols expected of our industry.

OKEL will happily upgrade your existing factory heater systems. Whether you’re looking to reduce operational costs by upgrading your existing system, or are considering switching fuel types to lower carbon emissions. We’ve got you covered.

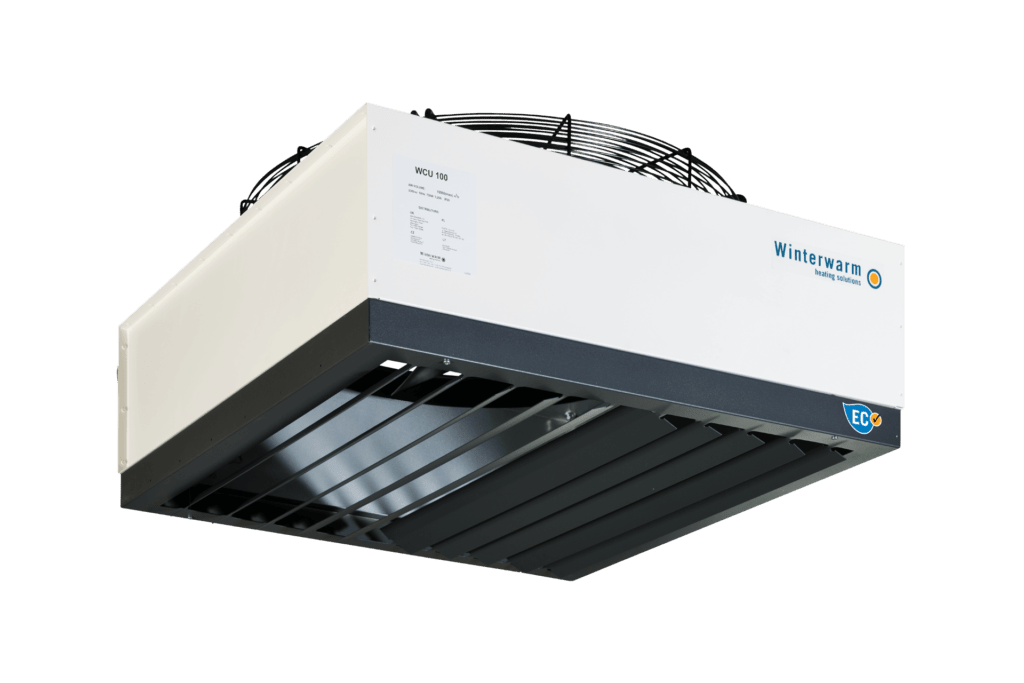

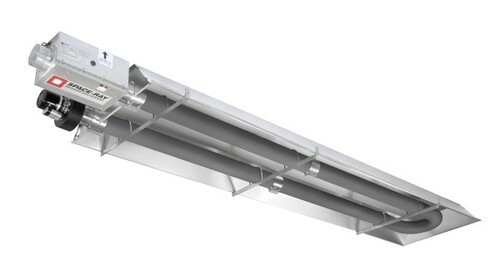

Some well-known factory heater brands we can replace include Winterwarm, Powrmatic, Reznor, Warmco, Combat, Benson, Harry Taylor, Ambi-rad and Space-Ray. Looking to achieve green business targets? OKEL is here to offer our expertise and deliver a high-efficiency alternative.

With challenging targets being set by the government to steer the UK to net zero by 2050, it’s essential that as businesses we all do our part to achieve the stringent targets set out.

When planning our bespoke designs, we always have “Energy Saving” at the front of our mind which reassures you that your system is of the highest efficiency. This can play a key role in helping you showcase the steps you’re taking as a business to successfully achieve green accreditations and targets.