Evaporative Cooling Ventilation Systems for Factories and Warehouses

As carbon emissions continue to rise, so do the outside ambient temperatures, resulting in more and more businesses searching for cooling and ventilation solutions to protect the quality of their manufacturing processes and stock and to provide a comfortable working temperature for staff and visitors.

Evaporative Fresh-air Cooling or Adiabatic Cooling as it can often be referred to is the most efficient and effective way to cool and ventilate large open plan areas and is designed to deliver the perfect ventilation and cooling solution for large industrial and commercial spaces; such as factories, warehouses, IT data centres, medical /pharmaceutical facilities, sports and leisure facilities, large retail outlets any many more.

The ventilation based cooling also reduces the risk of Covid transmission as unlike the more traditional refrigerant air conditioning systems that use re-circulated air, evaporative cooling systems circulate 100% fresh outside air throughout a building and introduces extraction to remove warm, stale and un-hygienic air and harmful refrigerants and pollutants.

By introducing Evaporative Cooling as an integral part of a balanced Ventilation system means that the temperature of a building can be controlled even on the hottest of days.

Benefits of Evaporative Fresh-air Cooling

- Improved Air Quality - Completely natural cooling process that introduces 100% fresh air, with regular air changes per hour, and extraction to remove stale un-hygienic air and harmful refrigerants and pollutants from within the premises.

- Removes the need for harmful refrigerant gases therefore making it an environmentally friendly cooling solution.

- Delivers operational energy costs approximately 90% less than the equivalent rated refrigeration based cooling system by achieving 35 kw of cooling for 1.5 kw of electricity consumption

- Non-recycled air

- Spot cooling particular areas of a facility where protection of products or machinery is critical

- Effective cooling whilst doors, windows and roller shutters remain open unlike air conditioning systems that operate in closed environments

- Happy, Healthier and a more Productive work force

Find the Perfect Cooling and Ventilation Solution for your Workplace

A standard Evaporative Cooler system based on an average air flow of 12,000 m³/ hr is estimated to cost only £0.142 per hour – Please note, energy tariffs vary

Take a look at OKEL’s most recent Evaporative Cooling Projects

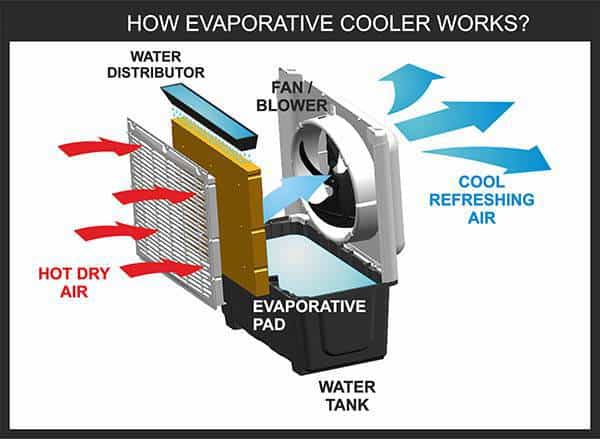

How Does Fresh-air Evaporative Cooling Work?

Our chosen Evaporative Cooler has 2 operational modes, pure ventilation, and cooling, with the balanced ventilation system supporting the requirements of the building and its application.

In cooler weather the units will operate in Ventilation Mode, which will be for the majority of days of the year in the UK. In this mode, the fan within the cooler is used to bring fresh air into the premises.

On warmer days, the units operate in Cooling Mode. The cooling takes place as the warm air is drawn over wetted filter pads and the water naturally evaporates into the air as it gives up the heat required to evaporate the water.

Fresh cool air is introduced into the building to cool it and the hot exhaust air is removed through open doors and windows and with the introduction of extraction fan/s to cool the building.

By using evaporative cooling as an integral part of a ventilation system means that the temperature of a building can be controlled even on the very hottest of days. In fact, the hotter the outside temperature and the lower the humidity, the greater the cooling effect.

The table below shows the potential cooling temperatures achievable at varying ambient temperatures and humidity levels

Maintaining working temperatures below 25°C on the hottest of days

% Relative Humidity | % Relative Humidity | % Relative Humidity | % Relative Humidity | |

Outside ambient temperature | 20% | 40% | 60% | 80% |

20°C | 12 | 14.5 | 16 | 18.5 |

25°C | 16 | 18.5 | 21 | 23 |

30°C | 19.5 | 22.5 | 25 | 28 |

35°C | 23 | 26.5 | 30 | 32.5 |

Evaporative Cooling is a completely natural way of producing cool fresh air & Ventilation and can save you up to

on cooling costs when compared to traditional refrigerant systems

Flexible Products and Installation Types

Contact OKEL to discuss your Cooling & Ventilation requirements

Evaporative Cooling and Ventilation Versus Refrigerated Air Conditioning

|

Consumes less than 10% of the electricity of an equivalently rated refrigeration based cooling system, such as air conditioning. |

Higher electrical demand due to the refrigerant circuit compressor |

|

Ventilation only (free cooling) option for cooler days, which helps to save energy |

Energy usage is high due to the constant need for mechanical refrigeration |

|

Supplies 100% fresh cooled air |

Uses mainly recycled air |

|

Can accommodate the very hottest of days |

Performance reduces at high ambient temperatures |

|

Low carbon dioxide footprint |

Higher carbon dioxide impact |